Maintaining the telescope requires regular dismounting and remounting of the 21 tonne primary mirror cell containing the 16 tonne mirror. This needs to be assembled to the 200 tonne telescope frame with an incredibly tight tolerance of repeatability of only+/- 20 microns. 30 years ago PILGRIM had provided the bolting solution but after many years service and use the original hydraulic bladder used to pressurise the bolts were well on the way to incontinence. This in turn made a simple job difficult and created additional unplanned and costly down-time during maintenance. Kevin Dee of ING explained that they were not prepared to tolerate any further unscheduled downtime and asked PILGRIM to help.

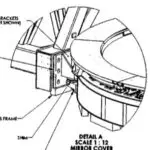

Application specific PILGRIM MorThrust Bolt design with built in load cell with locking collars:

3 off M36 x 377mm length with: