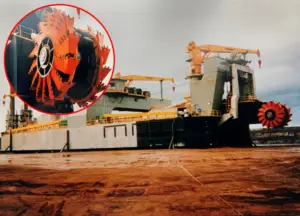

The multi-million dollar Land Dredger Delta 1 owned and operated by BHP Titanium Minerals, successfully operated in S.W. Australia extracting Titanium ore up to 45 Metres deep in a water filled lagoon. Using two 5 metre diameter bucket cutting heads directly mounted to an electrically driven gearbox, weighing in excess of 105 tonnes it processed 24 hours per day, delivering in excess of 27 million tonnes of ore per year.

The multi-million dollar Land Dredger Delta 1 owned and operated by BHP Titanium Minerals, successfully operated in S.W. Australia extracting Titanium ore up to 45 Metres deep in a water filled lagoon. Using two 5 metre diameter bucket cutting heads directly mounted to an electrically driven gearbox, weighing in excess of 105 tonnes it processed 24 hours per day, delivering in excess of 27 million tonnes of ore per year.At the design stage it was fully understood that at the business end the stresses and vibration would be extreme and the problem of securing the cutting heads to the tapered drive shaft and transmitting full torque values would require a special type of fastener. With estimated twice yearly removal of the heads, easy dismounting was critical.

2 off Pilgrim 1 metre Diameter PN Nuts, specifically designed to with stand the arduous environment including water / ore slurry and major vibrations. A nickel chromium molybdenum combination steel was selected offering a high tensile steel strength, with good ductility and wear resistance characteristics.

The Pilgrim nuts are hydraulically operated and used to drive up each cutter head up the tapered shaft to exert a design load sufficient to maintain maximum friction.