After review it was recognised that the alignment of the couplings bolt holes in mating flanges was a painstaking task and increases in difficulty the larger the turbines and generators involved. Rotating by baring rotors and generators each weighing anything up to 60 tons each means that overshooting the holes is very common and costly due to extended downtime. There was a need to find a way to rotate the final fractions of an inch while aligning the very heavy couplings.

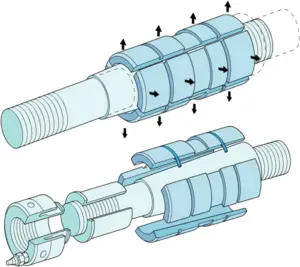

PILGRIM designed a Coupling Hole Alignment Tool CHAT utilizing the principles of the Radial Fit Bolt. This employs a Taper shank bolt hydraulically drawn into a matching sleeve. However, the alignment tooling employs a segmented sleeve to allow significantly greater radial expansion than the bolt sleeve. Normally 3 CHAT tools are enough but due to the size of the couplings 4 where required in this instance. Once the couplings are aligned, nuts are fitted and tightened. The tools are then re-pressurized to close the flanges, allowing Radial Fit Bolts to be installed.

“I found the CHAT tool extremely useful. Typically when we try to align a coupling so that we can install the coupling bolts it can be very difficult (especially on large turbine generators). You are trying to roll 60 tons of rotor fractions of an inch to get the alignment good enough to install the bolts. Usually you end up overshooting and have to come back and forth. Even when you can get a bolt in, you still have to try an jog the rotors back and forth again and again so you can get all of the bolts in.With the CHAT tool it is a one time shot. You install the tool, pump it up and all of the holes are perfectly aligned so you can get all of the bolts/sleeves in with ease. The other advantage of the CHAT tool is when you pull the couplings together with it. I have found that when we pull these big rotor couplings together with the bolts it can be very time consuming and you end up galling the nut spot-faces on the coupling faces unless you use a hardened washer”

Rick Spicuzza – Siemens Inc. (28th February 2002)