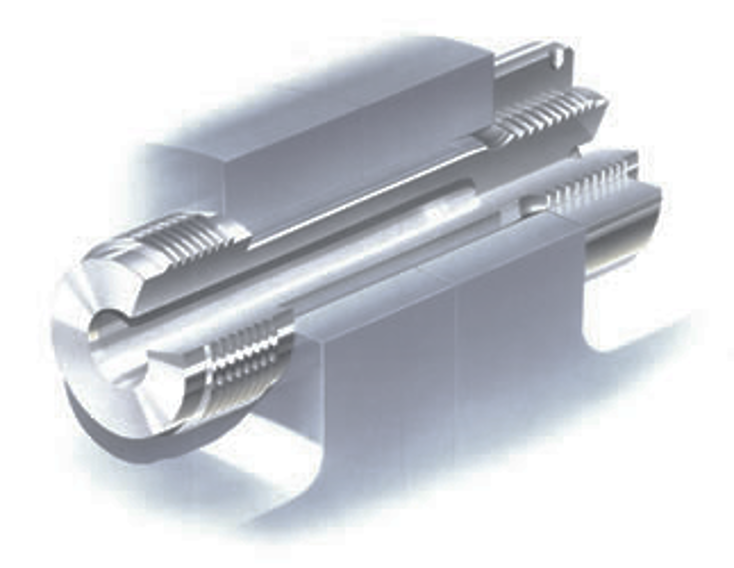

The MorGrip Bolt is a hydraulically actuated bolt designed to provide fast, cost-effective and trouble-free installation and removal.

The MorGrip provides a stark contrast to the installation of traditional shrink fit bolts, which often cause scoring of both the hole and bolt surface on removal. The Morgrip bolt, on the other hand, can be repeatedly installed and removed quickly without damage to either the bolt or the hole.

The principle on which the bolt works is based on Poisson’s ratio, which establishes that, when a round steel component is stretched within its elastic limit, it’s diameter will reduce by a known amount.

The MorGrip bolt was the first generation of Radial Fit Bolt. It has been proven in many applications, including Mine Winders, Nuclear Submarines, Naval and commercial marine propulsion systems.

The stretching force is applied through a hardened steel rod located down the centre of the bolt. Operating gear is screwed on to the head of the bolt. When pressurised, this exerts a force through the rod to stretch the bolt. As the bolt stretches in length it contracts in diameter according to Poisson’s ratio.

Once pressurised, the bolt can be clearance installed in the hole. A nut is attached (if a through-hole application) and lightly tightened. The pressure is then released to bring about a reduction in the length of the bolt and a corresponding increase in its diameter. The reduction in length achieves an axial clamping load as the increase in diameter simultaneously achieves a fitted condition. The bolt is now ready for service. It can be installed remotely from the pump unit by using the stop valve fitted to the operating gear to lock in hydraulic pressure. Removal is the reversal of this procedure.